- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

The main function:

(1) Function:cooling、transporting model sand,dust removal of model sand.

(2) The sand cooling quantity is large: it can guarantee molding sand to reach below 50℃. The single equipment efficiency is high.

(3)The good dust removal effect:lifting m。aterial’s structure design is reasonable.It can lift the model sand to the great extent. By axis flowing fan and dust removal machine, the dust is removed.

(4)The energy saving:the equipment’s motive power only has two 5.5KW electric engine、one 7.5KW water pump and one0.55KW fan.The energy consumption is low. If reaching the same sand processing quantity,the boiling and cooling bed needs 74KW.

(5) The appropriate cooling medium:the cooling medium is mainly water.Its specific heat capacity is large. The heat brought in unit time is most. The cooling speed is quick. It is convenient to take and it can be used circularly. The wind is second medium. The molding sand lifted in the equipment’s inner part is blown by back fan and is pulled out by front dust removal entrance. The dust removal efficiency is high. At the same time, it brings large heat.

(6)The equipment FM control,we can adjust the running speed of model sand in the horizontal cooling machine so we can get the purpose of temperature control.

(7)The node’s temperature control,It is used for detecting and controlling sand temperature.

(8)The equipment’s operation speed is slow without vibration; its structure is fixed;the operation is stable and it reduces the equipment breakdown rate.

Product Structure:

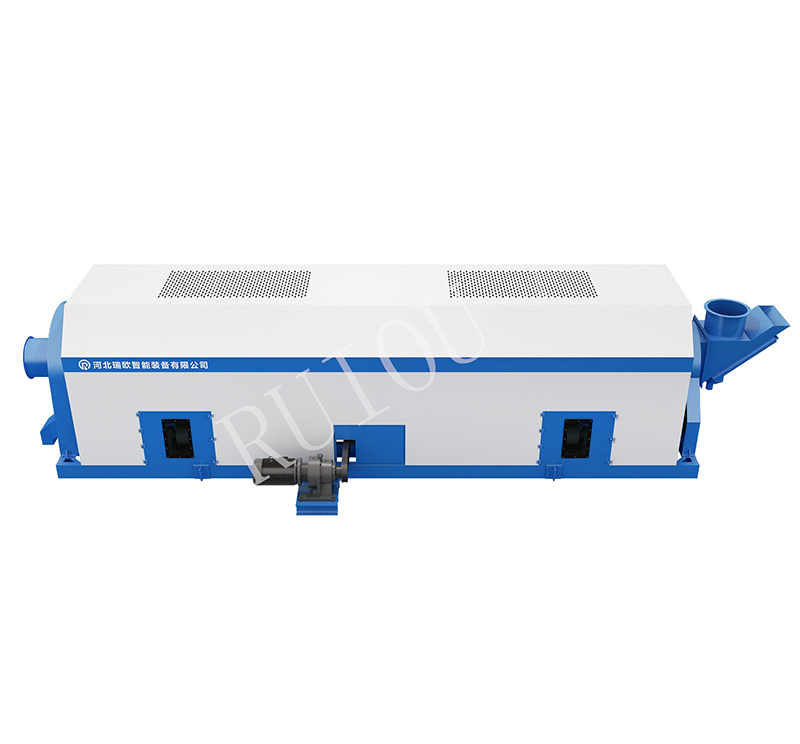

This equipment is a drum type rotary cooling equipment, which is mainly composed of the following parts:

1. Feeding unit (powder sieving)

2. Cylinder cover, drum, wet outlet, air inlet and discharge outlet.

3. Transmission unit

4. water cooling system

5. Atomization unit (only for nice foundry sand)

Transmission unit: variable frequency motor, variable frequency control. Tire drum drive and pinwheel drive.

Cooling methods: water cooling, air cooling, spray

Spray system: exclusive patent technology. atomization effect controlled automatically according to sand temperature to ensure outlet sand temperature.

Sand temperature detection system: equipment speed and spray system switch are controlled by PLC according to inlet and outlet temperature feedback.

Advantages of cooling equipment are explained as follows:

I. Technical parameters of the main cooling parts:

1. cooling fan: 0.75KW*1, drum air volume: 9300 m /h (inlet blowing)

0.37KW*1, blowing volume: 2008 m³/h ( top dissipation)

2. top heat dissipation plate: punched holes plastic board ( hot air been exhausted through top heat dissipation fan).

3. atomization system: self-priming pump ( flow: 1 m³/h, lift 15m)

4. spraying system: pipe DN 40, water amount 30m³/h(water pump 50m³/h)

5. conveyor roller drum: diameter 1600mm (drum speed 13r/min, variable frequency control speed)

Disconnect spiral structure inside drum. 1/3 of sand raised by the drum falls on the other side of the spiral line, while 2/3 falls back to the inside of the spiral line, which increases the travel of molding sand in the drum. At the same time, sand are mixed evenly which makes full cooling effect. In addition, the disconnect spiral structure reduces the weight of the equipment and enables the molding sand to travel about 110 meters.

II. Calculation of cooler performance:

Molding sand transfers heat to roller drum wall during convey. Spray system takes heat away through heat exchange to reduce temperature. Conclusion obtained after calculation of heat exchange and specific heat capacity.

The spray zone completely reaches the heat dissipation of the molding sand cooling temperature, and adds cooling methods of air-cooling system and variable frequency control roller speed. The cooling effect is fully achieved.

III. Site data acquisition:

According to site situation, sand temperature is monitored and tested. The following pictures shows a real-time monitoring of sand temperature drop in a certain period of time on a customer site. Inlet sand temperature is 116℃, and outlet sand temperature is 23.3℃.

Product structure advantages:

1. The equipment integrates cooling, conveying and dust removal. Through water cooling, air cooling and our company's patented atomized automatic cooling system (according to sand selection)to control the atomization effect according to the sand temperature. After triple cooling, sand temperature and dust removal efficiency are ensured.

2. Strong cooling capacity and large amount of transportation. Maximum conveying capacity can reach 30m³. Inside is equipped with a variety of spiral structures. Sand can be fully operated in the drum and can be cooled down from 150 to below 50 degrees Celsius.

3. High efficiency and energy saving. Less investment: horizontal cooler as the main cooling machine in sand treatment system, and compatible with the intermediate sand store, intermediate transportation, which saves investment of equipment.

Model Selection and Technical Parameters:

Model | Kind of Drive | Cooling Capacity | Power | Rolling Speed(FM) | Dimension |

ROWL-I | solid tire | 10m³/h | 11.75kw | 5-10r/min | 6700×2000×1850 |

ROWL-II | solid tire | 20m³/h | 16kw | 5-15r/min | 8200×2000×2250 |

ROWL-III | solid tire | 30m³/h | 23kw | 5-15r/min | 8200×2000×2250 |

ROWL-IV | pin wheel drive | 20m³/h | 18.5kw | 5-15r/min | 8200×2000×2250 |

cooling water requirements: circulating water supply, and the water temperature is less than 30 degrees Celsius. | |||||

(Note: the specific model is based on the actual design.)